From the Mailroom: Packing, Shipping & Receiving Records in Canadian Winters

Winter vinyl shipping. Cold temperatures. Condensation risks. Delivery delays.

Canadian record stores face unique challenges. November through March shipping requires specific protocols. Temperature fluctuations damage vinyl. Proper packing prevents warping.

Funky Moose Packing Protocol

Standard process. Proven results. Zero damage claims.

Step 1: Record Mailer Selection

- Bespoke record mailers

- Variable sizes: 1-LP, 2-LP, 5-LP capacity

- Corrugated cardboard construction

- Fold-to-fit design

Step 2: Size Adjustment

- Fold mailer to order specifications

- Single LP: 12.5" x 12.5" fold

- Multiple LPs: extend accordingly

- No excess space allowance

Step 3: Void Fill

- Bubble wrap sheets

- Corner protection priority

- Records immobilized completely

- Zero movement tolerance

Step 4: Sealing

- Heavy-duty packing tape

- All seam coverage

- Double-tape high-stress areas

- Weather-resistant adhesive

Step 5: Label Creation Computer magic. Shipping software integration. Automated address verification. Tracking number generation.

Watch the complete process: https://www.tiktok.com/@funkymoose.ca/video/7229720192077548806

Winter-Specific Considerations

Temperature shock. Major concern. Vinyl contracts in cold. Expands when warmed. Crack risk increases.

Pre-Shipment Storage

- Room temperature storage: 18-22°C

- 48-hour acclimation minimum

- Avoid temperature fluctuations

- Monitor storage humidity: 45-55%

Packaging Modifications

- Extra bubble wrap layers

- Moisture barrier integration

- Insulation padding

- Extended void fill

Timing Strategies

- Monday-Wednesday shipping preferred

- Avoid Friday shipments

- Weather forecast monitoring

- Holiday delay planning

Alternative Packing Methods

Method 1: Cardboard Sandwich

- Two cardboard sheets

- Record placement between

- Plastic wrap outer layer

- Bubble mailer insertion

Method 2: Foam Board Protection

- 1/4" foam board cutting

- Record dimension matching

- Tape edge sealing

- Standard mailer placement

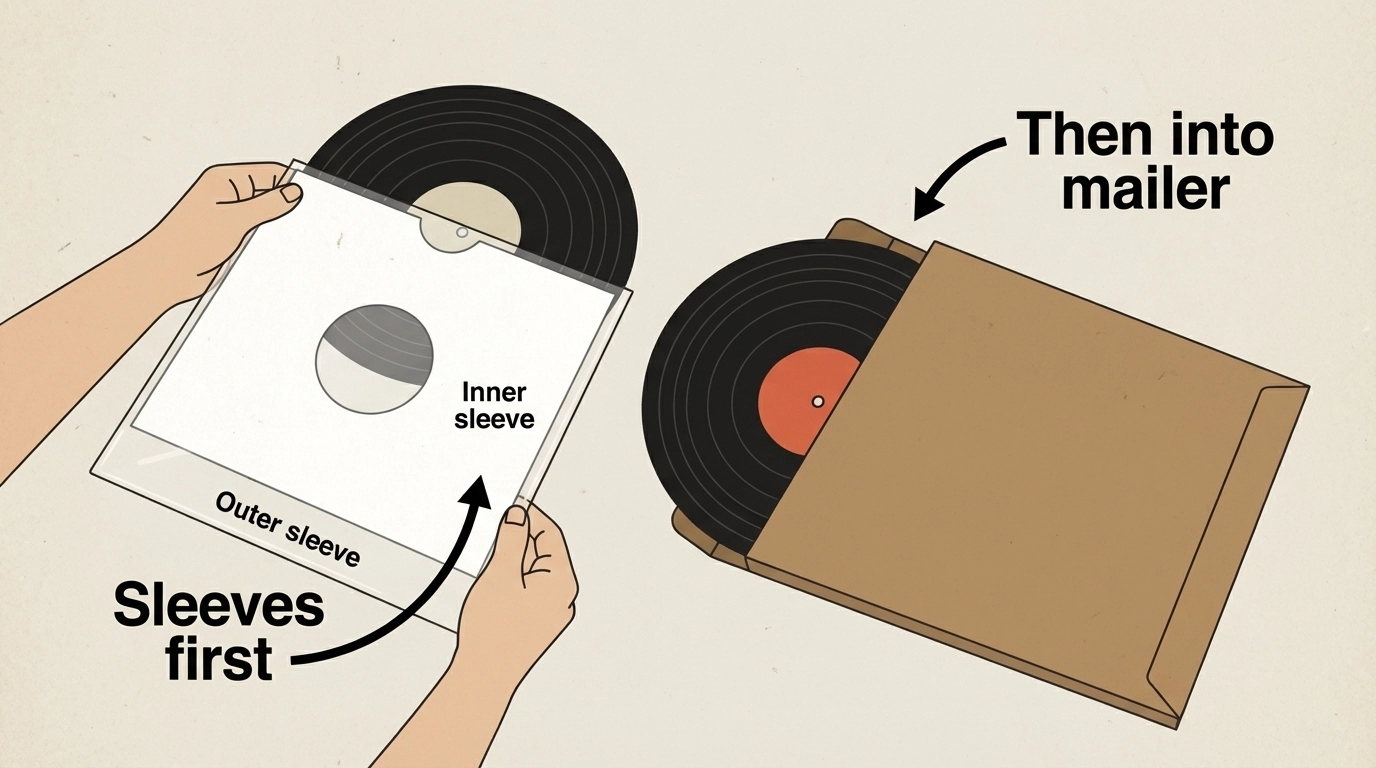

Method 3: Multiple Record Orders

- Plastic outer sleeves

- Individual record separation

- Cardboard dividers

- Extra padding allocation

Condensation Prevention

Primary winter threat. Moisture formation. Sleeve damage. Label deterioration.

Packaging Solutions

- Silica gel packets

- Plastic sleeve barriers

- Ventilation holes strategic placement

- Absorption material integration

Receiving Protocol

- Temperature equalization period

- 2-hour minimum wait

- Gradual unwrapping process

- Moisture inspection checks

Shipping Carrier Considerations

Canada Post Winter Performance

- Rural delivery delays common

- Weather-related suspensions

- Package holding procedures

- Temperature-controlled facilities limited

Private Carrier Options

- Purolator heated transport

- UPS temperature monitoring

- FedEx express services

- Regional carrier evaluation

Tracking Benefits

- Real-time location updates

- Temperature exposure alerts

- Delivery attempt notifications

- Hold facility information

Home Seller Best Practices

Individual collectors. eBay sellers. Discogs merchants. Same winter challenges apply.

Essential Supplies

- Record mailers: $2-5 each

- Bubble wrap: bulk purchase

- Packing tape: cold-weather formula

- Fragile stickers: visibility priority

Budget Options

- Pizza boxes: 12" LP fit

- Newspaper padding: free alternative

- Plastic bags: moisture protection

- Cardboard scraps: corner guards

Shipping Cost Management

- Weight optimization strategies

- Bulk shipping discounts

- Regional carrier comparisons

- Insurance evaluation

Receiving Records Safely

Delivery Timing

- Home presence requirement

- Signature confirmation

- Package retrieval speed

- Storage transition planning

Temperature Shock Prevention

- Garage staging area

- Gradual warming process

- Condensation monitoring

- Unpacking delay protocols

Damage Assessment

- Visual inspection procedures

- Warp detection methods

- Seam split identification

- Return process initiation

Common Winter Mistakes

Insufficient Padding Result: corner damage, seam splits, warp formation.

Immediate Unpacking Result: condensation damage, sleeve deterioration.

Inadequate Sealing Result: moisture infiltration, temperature exposure.

Poor Timing Result: extended cold exposure, delivery delays.

Record Store Operations

Inventory Management

- Cold storage protocols

- New arrival processing

- Customer order priorities

- Shipping schedule coordination

Staff Training Requirements

- Packing procedure standardization

- Quality control checkpoints

- Customer communication protocols

- Damage report procedures

Technology Integration

Shipping Software

- Address validation systems

- Carrier comparison tools

- Tracking integration

- Cost optimization features

Inventory Systems

- Stock level monitoring

- Reorder point triggers

- Seasonal demand forecasting

- Customer notification automation

Regional Variations

Prairie Provinces

- Extreme cold exposure

- Extended shipping windows

- Rural delivery challenges

- Infrastructure limitations

Coastal Areas

- Humidity fluctuations

- Temperature moderation

- Storm-related delays

- Marine environment factors

Northern Territories

- Limited carrier service

- Extended delivery times

- Weather-dependent access

- Cost premium considerations

Quality Control Measures

Pre-Ship Inspection

- Visual condition assessment

- Packaging integrity verification

- Label adhesion testing

- Weight confirmation

Customer Communication

- Shipping notification protocols

- Tracking information provision

- Delivery expectation management

- Issue resolution procedures

Winter vinyl shipping requires precision. Temperature control. Proper materials. Timing consideration.

Canadian collectors depend on proper handling. Record stores maintain reputation through consistent quality. Winter challenges create opportunities for service differentiation.

Professional packing prevents damage. Customer satisfaction increases. Return rates decrease. Business growth continues through challenging seasons.

Visit Funky Moose Records for winter-ready vinyl selection. Expert packing guaranteed.